Matching ink to all attributes of the printer – a new way to do ink

Print Service Provides (PSPs) acknowledge the need to change in order to meet the future needs of their customers. According to InfoTrends’ research 2015, the wide format market is expecting to grow from 19.3 billion in 2013 to 22.3 billion by 2018 and clearly shows the opportunity this market holds. As this market is becoming more sophisticated by offering a greater range of application possibilities, creative print shops are encouraged to utilize newer printer technologies and thus demanding more from the printer technology they are using. In addition, as wide format is becoming a mainstream industry with higher competition rates, margins are eroding, leading print shop owners to search for more cost efficient solutions.

The rapid market growth combined with economic pressures lead to the point where non-OEM inks (sometimes referred to as alternative inks) began to appear and rapidly gained popularity. Over the years non-OEM inks have evolved dramatically and today are ranked equally to OEM inks.

In the past several years the leading trend that guides inkjet ink manufacturers is the need to develop a perfect synergy between printers and their inks. Working extensively to develop this synergy, the first company to tackle this was Bordeaux Digital Printink, which introduced in 2008 a technology that soon became the standard for ink manufacturers – the Mix&Match solution for seamless conversion from OEM to non-OEM inks. Nowadays, Mix&Match is the standard for non-OEM ink manufacturers.

Until 2008, non-OEM inks were limited in their performance due to one main limitation- conversion was difficult to the end user and required complete conversion of all colors, flushing of the printer and creation of new ICC profiles. The Mix&Match solution was a breakthrough concept that changed the way print shops conceived non-OEM inks. Mix&Match inks were compatible with OEM inks both in chemical attributes and in color enabling mixing together with the original inks, without difference in colors after the conversion.

Mix&Match inks eliminated many of the obstacles for PSPs wanting to move to non-OEM inks. This game changer concept gained popularity among print shops as it saved them money and time while maintaining high quality printing.

Extensive research of the wide format market trends and leading experts in the field revealed interesting facts. The main barrier to switching to non-OEM inks today is the installation/conversion process that required a technician and printer downtime. Furthermore, non-OEM ink manufacturers are taking into account only the print head technology when matching ink to a printer and are not considering other technical attributes of the printer. Yet, there are additional criteria that influence the adaptation between the ink and the printer to yield perfect printing quality.

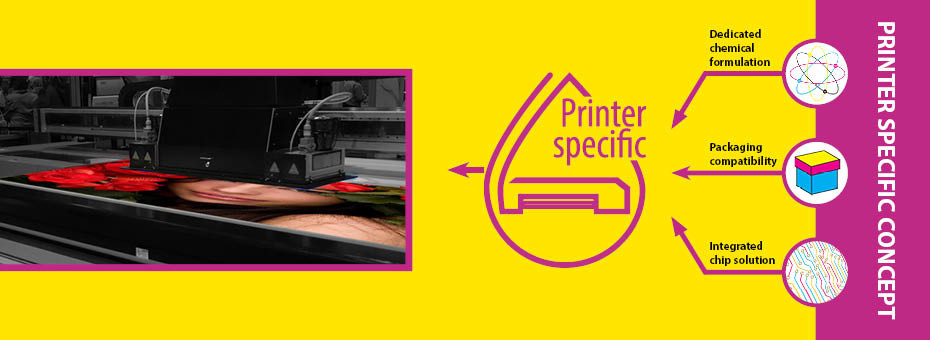

Printer manufacturers are constantly developing higher speed printers whose capabilities are supported by more than just new industrial printheads which are capable of faster printing. These manufacturers are offering specific inks for specific printer models that complement the printer so why shouldn’t non-OEM manufacturers follow the same standard? Dedicated inks for specific printers that are fully compatible with the printer’s technical attributes creates a perfect synergy between the printers and their inks and enables better printer performance.

When formulating inks for printers there is no one formula that will fit all types of printers. When looking at the technical attributes of different types of printers, even when two printers have the same printhead, there are other technical attributes that are different and make each printer unique. Heating and drying systems, printhead voltage and print speed, different tubing systems, different wavelength of UV lamps for UV printers and ink packaging are all characteristics that make every printer unique and requires specific ink adaptation. Furthermore, if the ink is not developed for a specific printer, it will not be 100{9711269676131cffc9f3e68bda16ea56bfa4568e90b74b1da79a64a65a632733} synergized with the printer and will not fully utilize its capability.

In the past couple of years Bordeaux identified this gap in the market and started working on ink solutions that fulfill this need. An in depth process has begun in the company, in which the entire product line has been reviewed and inks were re-formulated by the R&D department with printer specific modifications.

Printer specific inks that match the technical specifications of the printer can make the difference between a good and a great print. These inks have been formulated for, and then thoroughly tested on, specific printer models so they are compatible with the printer parts, its feeding system and its technical attributes.

There is a high demand for printer specific solutions across all technologies of the graphic arts section. The end users are eager for solutions which are plug & print and do not require technical support for installation. Since each printer has its proprietary features, it is mandatory to provide a solution which is fully compatible with the specific printers and does not require neither a technician to perform the conversion nor substantial printer downtime or modifications. Ink delivery system bypasses, open bulk systems and other improvised packaging solutions have always created uncertainty and fear in printer owners. These solutions are prone to failures and reduce the print quality.

For this reason the second characteristic of printer specific inks is the OEM equivalent packaging. Each ink solution needs to be supplied with a compatible packaging for the printer it is intended for. The dedicated packaging along with the unique ink formulation provides zero downtime installation which does not require a technician assistance and can be done by the printer operator.

The last barrier for conversion to non-OEM inks are chip protection on the printers. Printer specific inks provide a solution for this as well and are supplied with a chip solution that is adapted for each printer. Thus assuring that the conversion would be as transparent as possible.

Bordeaux believes that these three key benefits of printer specific ink- printer specific chemical formulation, compatible packaging and chip solution will help making printer specific ink the new benchmark of the industry.

Addressing environment compliance and customer satisfaction, UV cured inks are emerging as the frontier of wide format printing as they allow printing on a wide range of substrates.

The main challenge that non-OEM ink manufactures are faced with is the lack of an easy plug and print conversion solution for UV printers. UV printers are far more complex than solvent ones, with many more attributes to consider, when manufacturing inks. The printers’ complexity combined with the high price of UV printers can explain why PSPs are reluctant to use non-OEM UV inks. Difficult conversions and relatively advanced technical knowledge are needed for successful conversion to non-OEM ink.

One of the main feature of UV printers is the curing lamp. A standard UV lamp has a broad spectrum of wavelengths which affects the ink or coating formulation. Not all lamps are the same. Lamps differ in the UV wavelength output, as well as the peak energy output. The mixture of photoinitiators in the ink must adhere to the exact wavelength of the curing lamp. When formulating inks for different UV printers and different UV curing lamps, the photoinitiators are used to match the wide-spread wave length of the UV lamps. A careful selection of the right photoinitiators to match the energy peak of the curing lamp is a must. Thus, the degree to which the UV energy is synchronized with the photoinitiators in the ink formulation will dictate how the printer correspond with the ink.

Guy Evron, Marketing manager of Bordeaux explains: “once we have identified the gap in the market and the need for better ink solutions to UV printers we have started to work on a new line of printer specific inks. All printer specific inks have been designed from scratch in order to fit the best-selling printers in the market. After 2 years of development and rigorous field testing Bordeaux is proud to be the first non-OEM ink manufacture to develop printer specific inks for the leading UV printers on the market such as Oce® Arizona™, Efi® Vutek QS™ and Fuji® Acuity™”.

As said, one of the largest challenges in the print industry today is the erosion in margins. Non-OEM inks have been a main solution to this problem over the years and will continue to be a major consideration in the purchase of a new printer. Print shop owners are constantly searching for new ways to save on costs without sacrificing quality and printer specific inks might be just what is needed in order to tip the scale.

Find out which ink is right for your printer

Oops! We could not locate your form.